Logo Compliance Control System

Glass containers are generally produced in very large volumes through a molding process; the prolonged use of the mold lead to its wear, with the consequent variation of the required characteristics of the finished product.

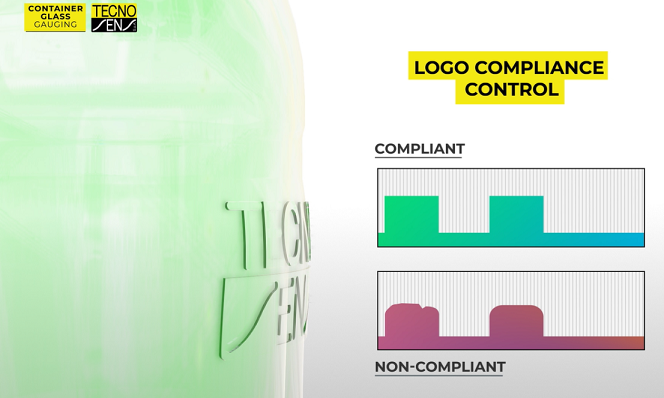

Printed logos on bottles are particularly affected by the wear of the mold, they change shape and size depending on the age of the mold that created them.

Therefore, it becomes essential to check that the printed logos are compliant and meet the requirements; in order to do this, two approaches can be followed: to manually check a few bottles per hour, and rely on the subjectivity of the operator, or to achieve objective measurement and complete traceability on 100% of the production thanks to Caliber Logo Scan

Features:

- Objective and reliable detection of quality of the Logo

- Traceability of all measurements

- Up to 180 bottles per minute

- Non-contact reading technology

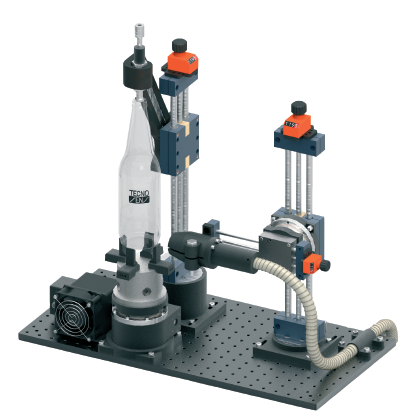

- Suitable for automatic lines or for laboratory

- Easily integrated in third part machineries

- Storaging of all data

- Easy Recipe creation and selection

- Statistical Process Control (SPC Quality)

- Real Time Diagnostic

It includes:

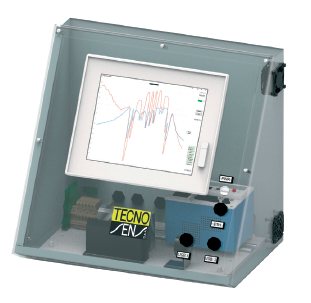

- panel PC touchscreen 12"

- 1 buzzer, programmable

- 6 digital Inputs, including Start Measurement input

- 6 Relays including OK - valid measurement and Alarms

- TCP/IP: XML protocol for data sharing