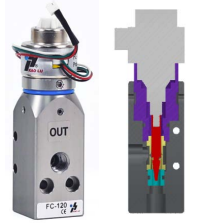

Flow control valve FC series

Proportional Flow Control Valve consists of PM series driver and FC series proportional flow valve. With an input signal either through analogue or digital, the needle inside the proportional valve moves proportionally to the signal. This series is able to control the flow rate of air and liquid with high resolution, high accuracy, and high repeatability. It is developed for industries that require a high degree of adjustment in flow rate.