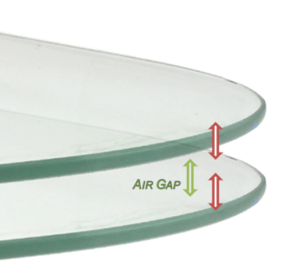

AirGap System - AGS

TECNOSENS AGS is a tool to identify and measure in fast and accurate way the spaces that are created among the crystals, also said mismatch.

The system TECNOSENS AGS allows to save and analyze through statistic methods the captured data, hilighting the points where the glasses don't perfectly match.