To ensure maximum efficiency, the glass surface must be free of imperfections. At the same time, the same precision is also required for sensors and instruments dedicated to this sector.

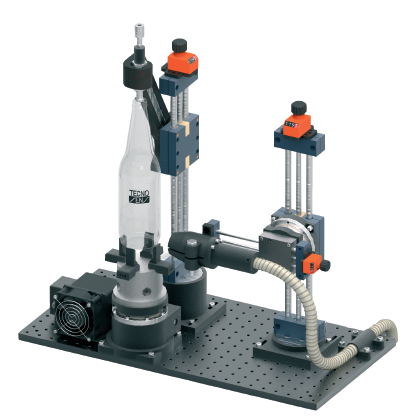

Product quality control, measurement and verification of thicknesses, contours and dimensions and monitoring of the production process: our sensors are essential for controlling all the phases that affect glass treatment.

With our solutions you can:

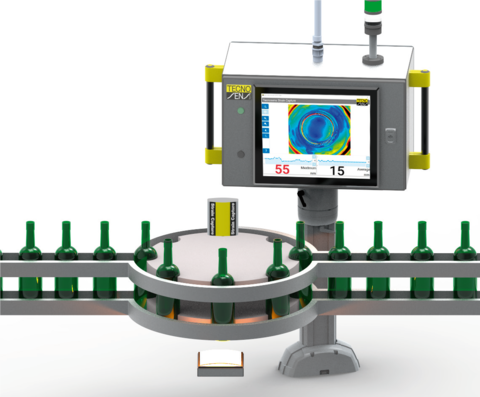

- Prevent mislabeling and identify any defects in the on-line production of glass bottles;

- Check the shape of a glass container, including straightness and internal diameter quickly and easily;

- Measure the thickness simultaneously, at different points;

- Check the quality of logos and writings printed on the glass container with a system that offers 100% traceability and objective measurement;

- Read the identification code on the bottles to be able to trace the mold that manufactured them quickly and accurately, in order to be able to trace the source of one of the variables that are the cause of bottle defects: the wear of the mold .

Find out below our solutions for the world of container glass, for quality control, measurement and production monitoring.